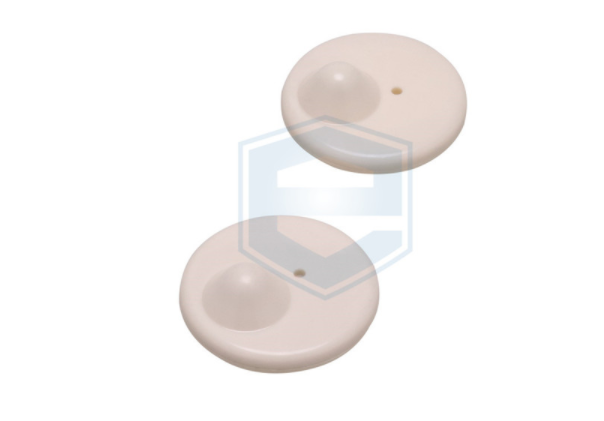

Every day, items under RFID devices are subjected to conditions such as dirt, mud, dust, soot, water, violent vibrations, chemicals, etc.

When looking for RFID solutions for hazardous environments, one of the most important components to consider is the RFID tag, as it will be subject to the same conditions as the item to which it is attached. Here are some tips on how to select tags and devices for applications in harsh environments.

1, Check to see if the tag has an IP rating, which will help determine how well the rfid tag protects against dust and water ingress.

2, If you are familiar with the environmental conditions, narrow down the tags based on what is most important - whether it is water resistance, impact resistance, or mountable materials.

3, Determine the best way to attach the tag to the asset. In some cases, using screw/rivet connections or a welder to weld the tag directly to the asset may compromise its integrity. Check with the tag manufacturer for their recommended attachment method.

4, Will your equipment be in close proximity to explosive materials or hazardous chemicals? If so, look for tags that are ATEX certified or encapsulated in special materials that are chemically resistant.

5, Testing is key - When it comes to label type, placement and attachment methods, the best advice is to test a variety of labels to understand their performance before selecting a specific label.

6, Tag placement on the asset is an important factor to consider. Find a location for that tag that does not restrict the movement of the asset, but also consider the position of the reader relative to the tag.

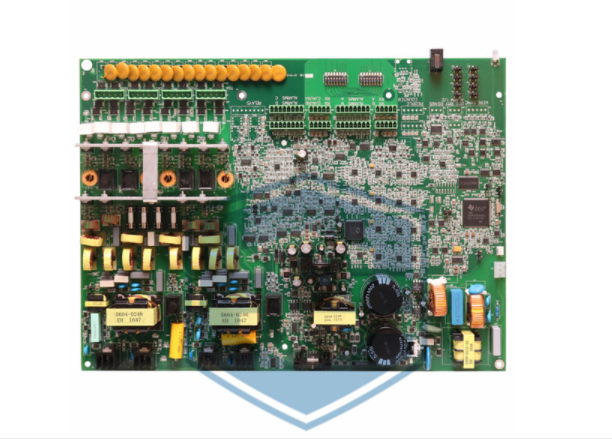

Because of the wide variety of devices and methods used to set up RFID systems, the following tips on choosing the right RFID device are extensive. Readers used in these types of environments should be rugged enough.

1, Will your device be around explosive items or in a hazardous area? Some RFID devices are ATEX certified for use in these areas.

2, Does the reader need to be installed in a vehicle or kept in an environment where equipment and/or machinery may vibrate? Check that the reader has been tested for repeated vibration before purchase.

3, The read range depends on many different factors. Most readers show the read range on their data sheet, but the reported range is based on the ideal environment. Test the reader in your environment to get a true range.

4, If the application requires a handheld reader, be sure to check the battery life and purchase additional batteries if you use the reader longer than the battery allows.

5, If the application requires a stationary reader, keep in mind that the reader needs to be connected to a power source, and choose the power source that best meets the needs of your application.

To learn more about RFID, check out our website. If you have any questions, please contact us at the button below.

Basic Approach to Preventing Retail Business Losses

Apr. 16, 2022

What You Need to Know about EAS Security Tag Alerts

Apr. 06, 2022